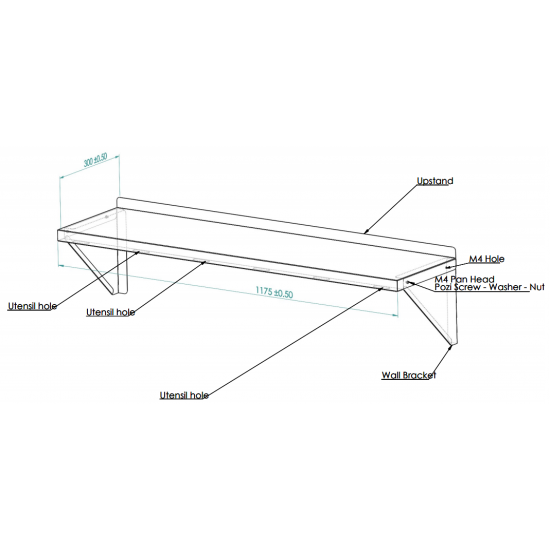

- Model: Stainless Steel Shelf

- Weight: 10.00kg

- Dimensions: 500.00mm x 300.00mm x 30.00mm

Available Options

Kitchen Wall Shelves

Our new and improved stainless steel kitchen shelves are manufactured in the UK fromÿstainless steel.ÿ We offer multiple lengths and holding brackets for price andÿconvieinece.ÿ The kitchen shelf comes flat packed and is easily assembled using the M4ÿscrews that come supplied with the shelf pack.ÿ The brackets just screw in place using an appropriate fixing for your type of wall.

We offerÿeasy fix wall brackets for connection of the shelf to the wall.

We have provided holes in the bottom edge of the shelf so spoons / ladels & other utensils can easily be hooked onto the shelf for convenientÿuse.ÿ We also have a unique bar that can ve used to suspended additionalÿutensils and serving spoons.ÿ Please ask for details and prices.

- Made from 100% Stainless Steel

- Made in the United Kingdom

- Heavy grade 1.00mm Stainless Steel material

- Choice of flat brackets or tube brackets (Please ring for tube bracket cost)

- Strong and durableÿshelving

- Great for busy kitchens, restaurants

- Store food, utensils, boxes and more

- Lowest price and highest quality kitchen shelving in the UK

- Corrosion resistant stainless steel

- Other sizes available

- 500mm length shelf

- 600mm length shelf

- 800mm length shelf

- 900mm length shelf

- 1000mm length shelf

- 1175mm length shelf

- We also offer a shorter depth version of 150mm (Depth - Front to back) if you need a narrow storage solution.

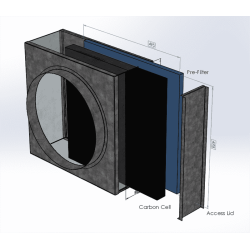

Q. Is it a legal requirement in the U.K to have extraction in a commercial kitchen?

A. In the UK, it is indeed a legal requirement to have extraction and ventilation in commercial kitchens. This requirement is governed by the Workplace (Health, Safety and Welfare) Regulations 1992, which mandate employers to provide effective and appropriate ventilation in every enclosed workplace, including kitchens. Mechanical extraction is recommended as a means of achieving effective kitchen ventilation. This regulation ensures the safety, health, and comfort of kitchen staff and patrons by controlling odours, reducing airborne grease, and minimizing fire risks. Compliance with these regulations is crucial for commercial kitchen operators in the UK.

Q. How often should commercial kitchen extraction be cleaned in the U.K?

A. In the UK, the frequency at which commercial kitchen extraction systems need to be cleaned is outlined by the TR19 guidelines, which are widely recognized within the industry. According to these guidelines, the cleaning frequency is determined by the amount of usage the kitchen sees:

- Heavy use (12-16 hours a day): Every 3 months.

- Moderate use (6-12 hours a day): Every 6 months.

- Light use (2-6 hours per day): Annually.

These intervals are recommended to ensure that grease accumulation is managed effectively, reducing the risk of fire and ensuring that the ventilation system works efficiently. Compliance with these guidelines not only helps in maintaining hygiene and safety standards but also in adhering to legal requirements.

Q. Do I need planning permission for a commercial extractor fan?

A. In the UK, whether you need planning permission for installing a commercial extractor fan can depend on several factors, such as the location of your property, the size of the extraction system, and its potential impact on the surrounding area (e.g., noise and odors). Generally, if the installation of an extractor fan involves significant changes to the building's exterior or affects the local environment, you may need to obtain planning permission.

For properties located in conservation areas or listed buildings, there are stricter controls, and planning permission is more likely to be required for any external changes, including the installation of commercial extractor fans.

It's essential to consult your local council's planning department before installing an extractor fan in a commercial kitchen. They can provide specific guidance based on your situation and the local regulations. This step ensures that you comply with the necessary planning permissions and building regulations, avoiding potential legal issues or fines.

What is a commercial kitchen canopy hood

A commercial extraction canopy hood, often found in commercial kitchens, is a crucial component designed to remove heat, smoke, grease, and other airborne contaminants generated during cooking. It ensures a safe, comfortable, and regulatory-compliant working environment by providing ventilation. These hoods typically feature advanced filtration systems, including grease filters and sometimes additional fire suppression systems to enhance safety. Made from durable materials like stainless steel, they are designed for easy cleaning and maintenance. The use of such hoods is vital for maintaining air quality, reducing fire risks, and complying with health and safety regulations in commercial food preparation areas.When selecting a commercial extraction canopy hood for your kitchen, the choice depends on your kitchen's size, layout, cooking volume, and the types of appliances used.

Here are the important types of canopy hoods and key considerations for selection:

1. Wall-mounted Canopy Hoods Description: Installed against a kitchen wall, ideal for ranges, griddles, and fryers placed along walls.

Selection Criteria: Choose if your cooking equipment is against the wall and you need effective smoke and grease removal from that specific area.

2. Island Canopy Hoods Description: Free-hanging units designed for kitchens with central cooking areas. They capture contaminants from all sides.

Selection Criteria: Opt for island hoods if your cooking stations are in the kitchen's center, requiring a 360-degree capture zone.

3. Low Ceiling Hoods Description: Specifically designed for kitchens with height restrictions, ensuring efficient ventilation without the need for high ceilings.

Selection Criteria: Ideal if your kitchen has low ceilings but requires efficient extraction.

4. Heat and Condensate Hoods Description: Specialized hoods for high-moisture environments, capturing steam and condensate along with smoke and grease.

Selection Criteria: Necessary for kitchens with heavy steam-producing appliances, like dishwashers or pasta cookers.

5. Make-Up Air Hoods Description: These hoods introduce fresh air back into the kitchen to replace the air extracted, ensuring a balanced environment.

Selection Criteria: Choose if your kitchen requires a steady flow of fresh air to combat negative pressure issues.

Selection Tips:

Volume and Type of Cooking: Heavier cooking volumes and greasier foods need more powerful extraction. Space and Layout: The kitchen's size and equipment layout determine the hood type and size.

Local Regulations: Ensure the chosen hood meets all local health, safety, and building codes.

Energy Efficiency: Consider models that offer energy savings without compromising on performance.

Professional Assessment: Consulting with a ventilation expert or engineer can provide customized advice based on your specific needs. Selecting the right type involves balancing your kitchen's operational needs with health and safety regulations while also considering the physical constraints of your space.